Merci à tous nos clients!

*depuis 2020

À PROPOS DE NOUS

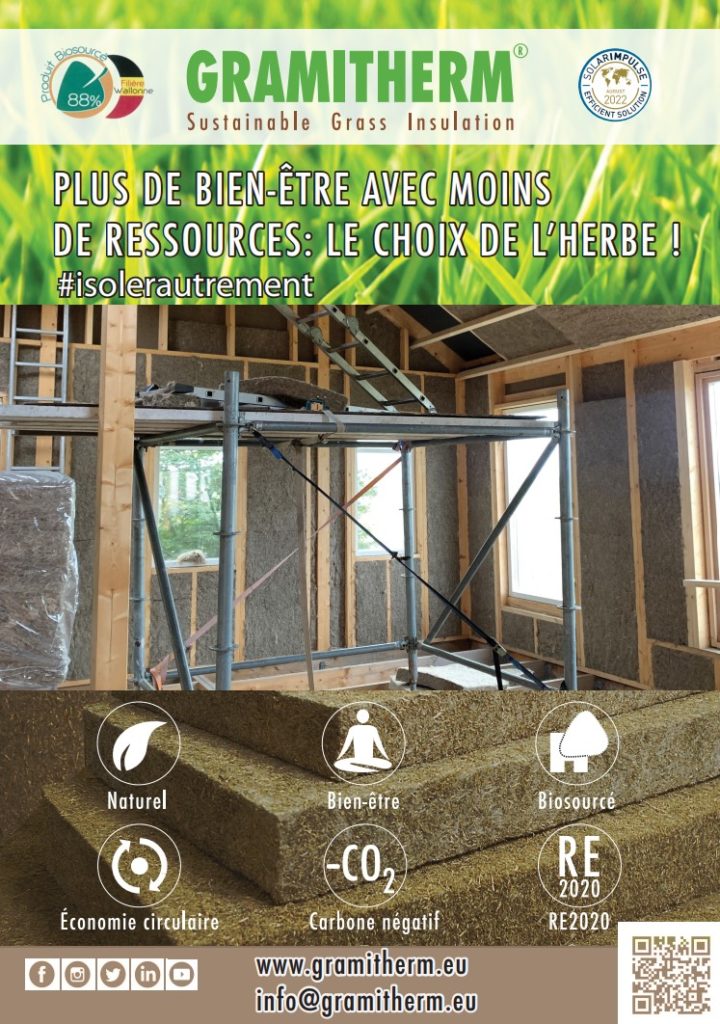

La société Gramitherm Europe SA a été créée à Auvelais en 2019 pour commercialiser les produits de la marque déposée Gramitherm®, un procédé suisse exclusif permettant de fabriquer une nouvelle génération de panneaux isolants naturels et écologiques à base d’herbe « perdue ».

Gramitherm® est le premier matériau d’isolation 100% propre qui présente le meilleur bilan écologique dans sa catégorie !

Partout où l’herbe pousse, Gramitherm® a sa place comme solution d’isolation aussi efficace qu’écologique.

De par sa nature, le concept Gramitherm® est universel et permet d’exploiter une ressource quasi « illimitée » et rapidement reconstituable.

GRAMITHERM :

Adapté aux projets résidentiels et professionnels (neuf et rénovation)

Une technologie suisse exclusive utilisant l’herbe « perdue »

Une offre unique de panneaux isolants à base de fibres d’herbe

Gamme standard et sur mesure chantiers (flexibilité de production)

Retrouvez toutes nos vidéos sur la chaîne YouTube

DERNIÈRES ACTUALITÉS

DTA

Nous sommes heureux de vous informer que Gramitherm dispose à présent des deux documents suivants : Le Document Technique d’Application Mur n° 20/22-508 publié le 11/04/2024 Le Document Technique d’Application Comble n° 20/22-510 publié le 11/04/2024 Nous remercions le FRD – CODEM qui nous a accompagné dans la constitution de ces dossiers et le CSTB pour leur assistance tout au long de cette

Formation Pose Gramitherm + Ampack 24/04/24

Nouvelle date pour la formation pose des panneaux Gramitherm associant la technique pose des membranes Ampack. Venez nous rejoindre la matinée du mercredi 24 avril 2024 sur le site de production à Auvelais pour devenit pro du produit! Plus d’infos et Inscriptions via Anne-Sophie Blomme ou Laurent Son

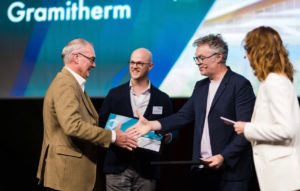

BATI-Awards 2024

Gramitherm a remporté le BATI-Awards 2024, prix du jury au Salon BATIMOI! Merci au jury pour cette reconnaissance pour notre solution isolante à base de fibres d’herbe, durable et éco-responsable. Félicitations également à Belga Solar qui a reçu le prix du public. Merci aux membres du jury Philippe Coulée, Hugues Kempeneers, Nicolas Pinon, Julien Bil. Merci pour sa présence à

TRENDS IMPACT AWARDS 2022 – Circular Economy

On 30 November 2022 a gala event took place in Brussels with Trends-Tendances, PwC Belgium and Antwerp Management School crowning the projects that drive impact and sustainability. Gramitherm is very proud to have been recognized as most sustainable company in the circular economy category and to receive the Trends Impact Award for this category !

Lauréat Energie Sprong

Catégorie 3 : Solutions hors-site intégrées de façades isolantes améliorant l’efficacité énergétique des bâtiments éducatifs et les conditions de travail des élèves, parrainée par Cergy Université et la ville de Trith Saint-Léger. Solutions lauréates : Panneaux ITE Vestack du groupement Vestack, Weber, Solab, Architecture Pelegrin et Aldes, solution avec une standardisation poussée, un prix abordable, et un compromis prometteur entre

GRAMITHERM RÉFÉRENCÉ SUR LA CALCULETTE DE VALEUR U UBAKUS

Le calculateur de la valeur U examine le composant (par exemple, un mur, un toit, le plafond,…) sur l’effet d’isolation, protection contre l’humidité et la protection de chaleur estivale:.. Retrouvez la suite sur Calculette de valeur U | ubakus.com et essayez Gramitherm®!